XPS

X-ray Photoelectron Spectroscopy (XPS) is used to identify and quantify surface elements via detection of valence and core electrons with binding energies characteristic of those elements. Wide-range survey spectra are used to detect elemental composition over a depth of around 10 nm, with most of the signal coming from the first few nm. Chemical shifts found in high-resolution narrow region spectra will then provide insight into chemical environment and oxidation states.

XPS can be used to characterise organic, inorganic and metallic thin films and semi-conductors, in the form of surfaces and powders. A charge neutraliser allows powders and insulating materials to be measured by compensating for the spectral shift due to surface charging.

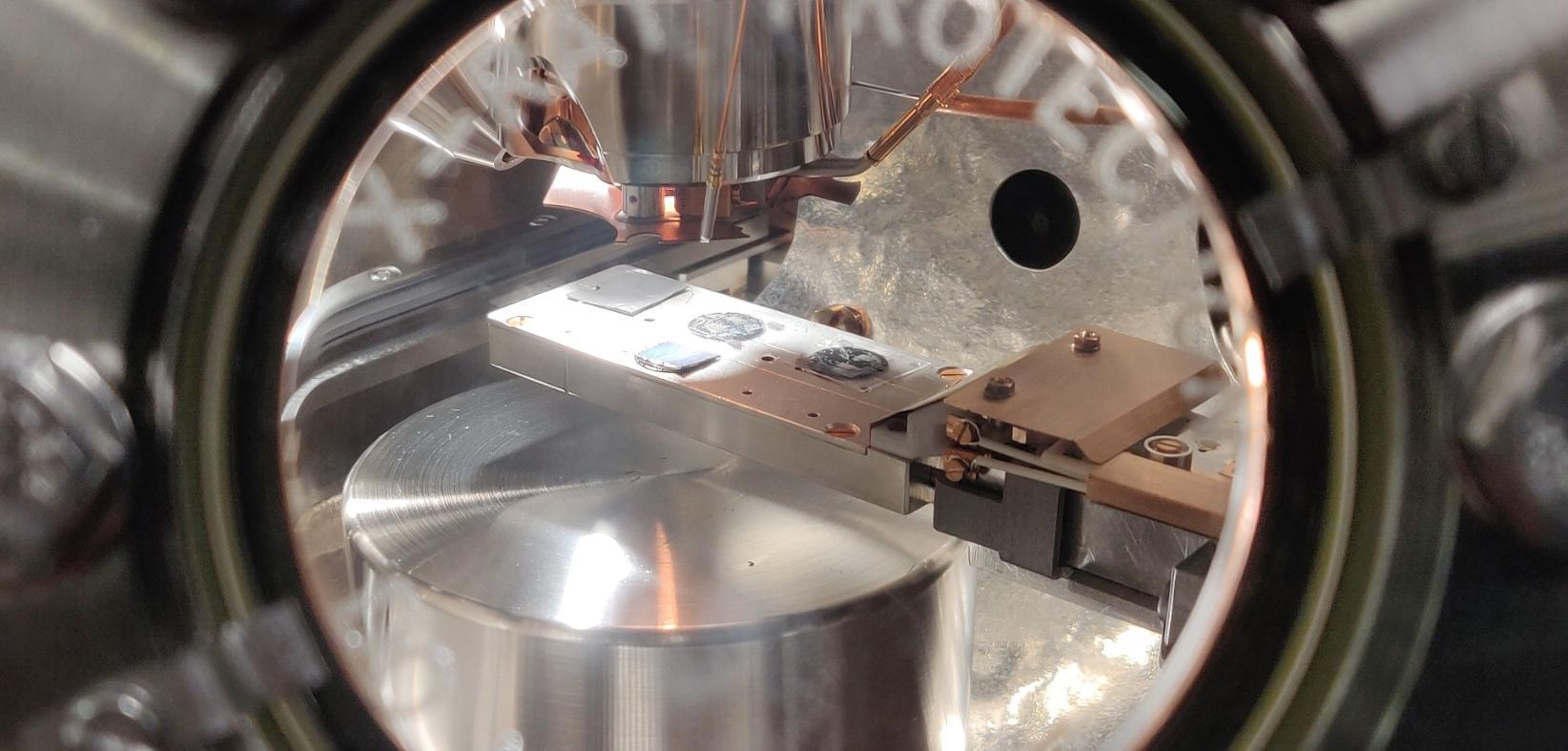

The Kratos AXIS Supra+ is equipped a variety of excitation sources and experimental capabilities:

- Dual source X-ray filament (Ag/Al) to cover a wide range of possible emission energies for XPS.

- Angle-resolved XPS and XPS imaging.

- Gas cluster ion source (GCIS) that produces monatomic or 1000+ cluster Argon ions for surface etching and depth profiling.

- Ultraviolet photoelectron spectroscopy (UPS) accessory to probe low binding energy valence electrons with improved sensitivity and resolution over XPS – this allows the user to determine valence band edge and density of states.

- Electron source power supply for reflection electron energy loss spectroscopy (REELS), which can determine electronic band gaps or energy levels of unoccupied molecular orbitals.

- N2 purged glovebox and sample transfer arm to help load air-sensitive samples.

- Heating and cooling accessories to bring sample holder up to +800°C and below -100°C using liquid nitrogen.

Single piece samples should be at least 3 mm x 3 mm in size, and ideally be no larger than 15 mm x 15 mm. They should also be no thicker than 6 mm. Samples outside this range can be considered on a case-by-case basis.

Powder samples can be submitted, but for XPS only, and must be at least 100 mg.

For enquiries, please contact Dr. Chris Kelly and consult the FAQ and access procedure documents for information.