Developing detection of gravitational waves, boosting our understanding of the Universe

Published: 19 November 2024

Highly reflective (HR) optical mirrors are required for the detection of gravitational waves generated from cosmological events. Kirstin Saunders is working on improving their sensitivity.

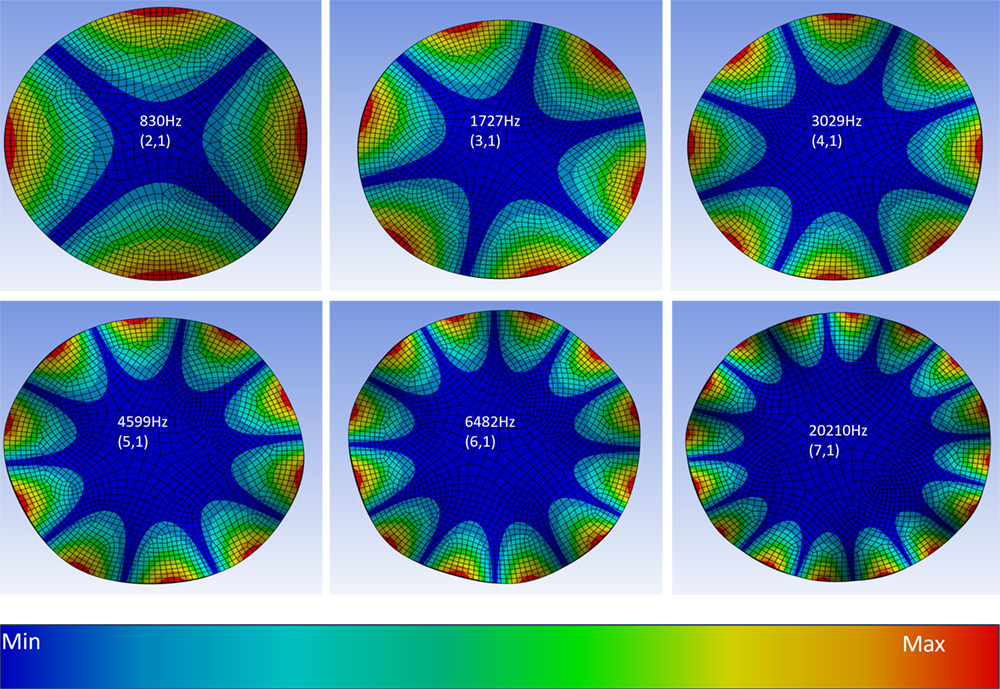

Highly reflective (HR) optical mirrors are required for the detection of gravitational waves (GW) generated from cosmological events. Their analysis will boost our understanding of the Universe, providing unique opportunities to test aspects of General Relativity and open new fields in astronomy. However, coating Brownian thermal noise (CTN), arising from thermal vibrations in the HR mirror coatings, is a critical noise source, limiting the sensitivity of current GW detectors. CTN can be reduced by decreasing the mirror’s temperature, so there is considerable interest in studying both coating and substrate properties at cryogenic temperatures. To determine the CTN, the mechanical loss of the materials is found using a gentle nodal suspension system, finding the resonant modes, and tracking its oscillations, shown in Figures 4 and 5.

Silicon nitride (SiNx) is considered one of the most promising high refractive index materials (n > 2) in distributed Bragg’s reflectors (DBR) structures working at 1550 nm laser wavelength, for GW detectors, due to its low CTN at cryogenic conditions. Moreover, the possibility to tune SiNx stoichiometry producing a refractive index above and below 2, allows the design of a DBR purely based on SiNx multilayers.

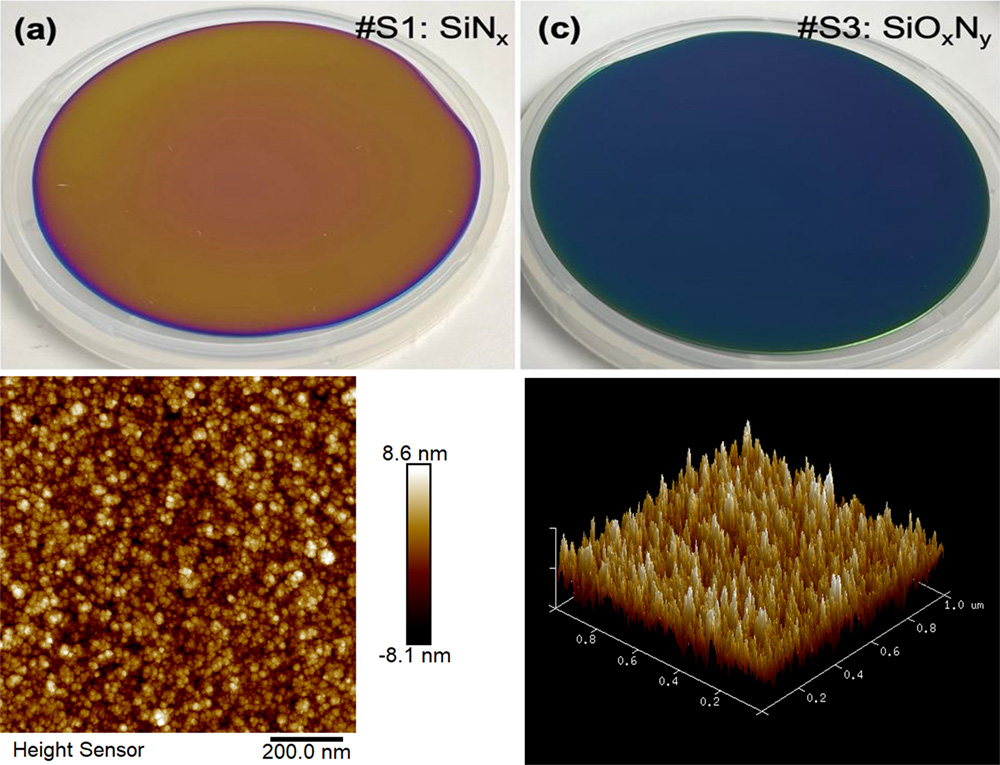

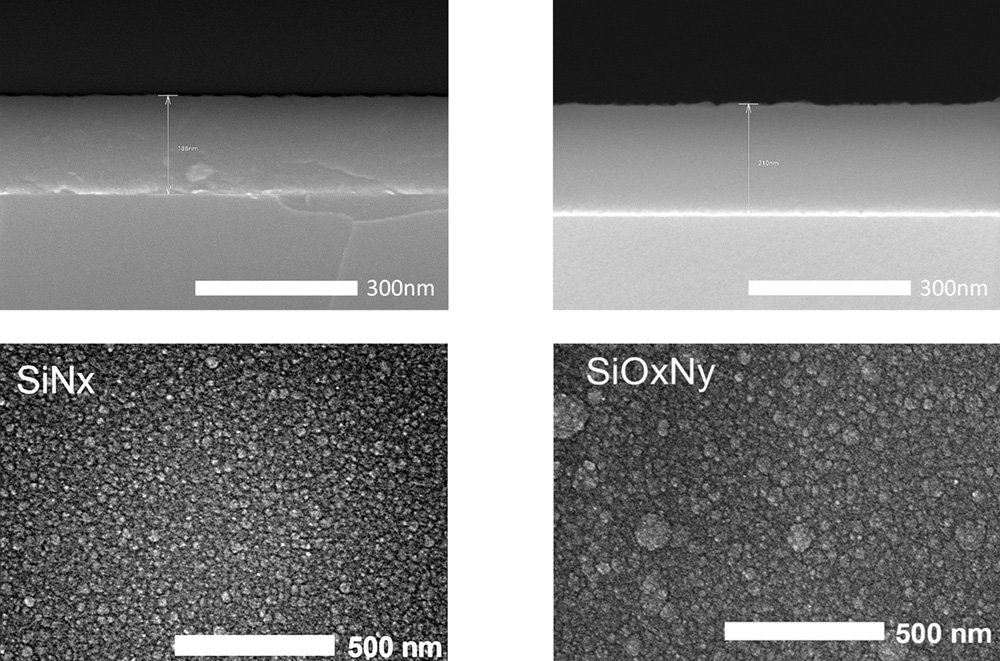

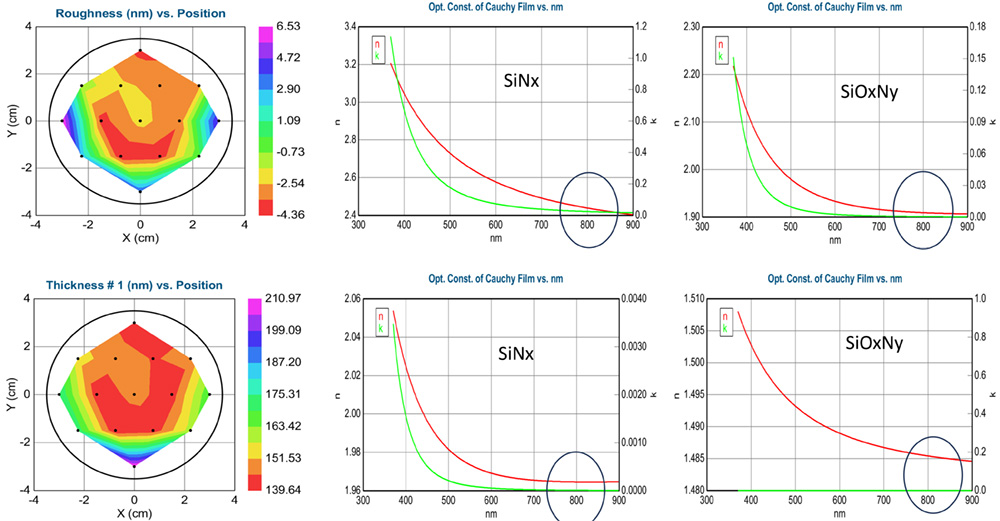

The optimization of composition and structure of SiNx thin films to refine optical (refractive index, and optical absorption coefficient), and morphology (surface roughness, defects) have been carried out mainly using the Delta SPTS plasma enhanced chemical vapor deposition (PECVD) system in the JWNC, shown in Figure 1. Characterization of both SiNx and a new alternative silicon oxynitride thin films have been carried out using AFM, SEM, and Spectroscopic ellipsometry, all within the JWNC shown in Figures 1, 2 and 3.

+++

Figure 1

---

+++

Figure 2

---

+++

Figure 3

---

+++

Figure 4

---

+++

Figure 5

---

First published: 19 November 2024