Industrial Ultrasound

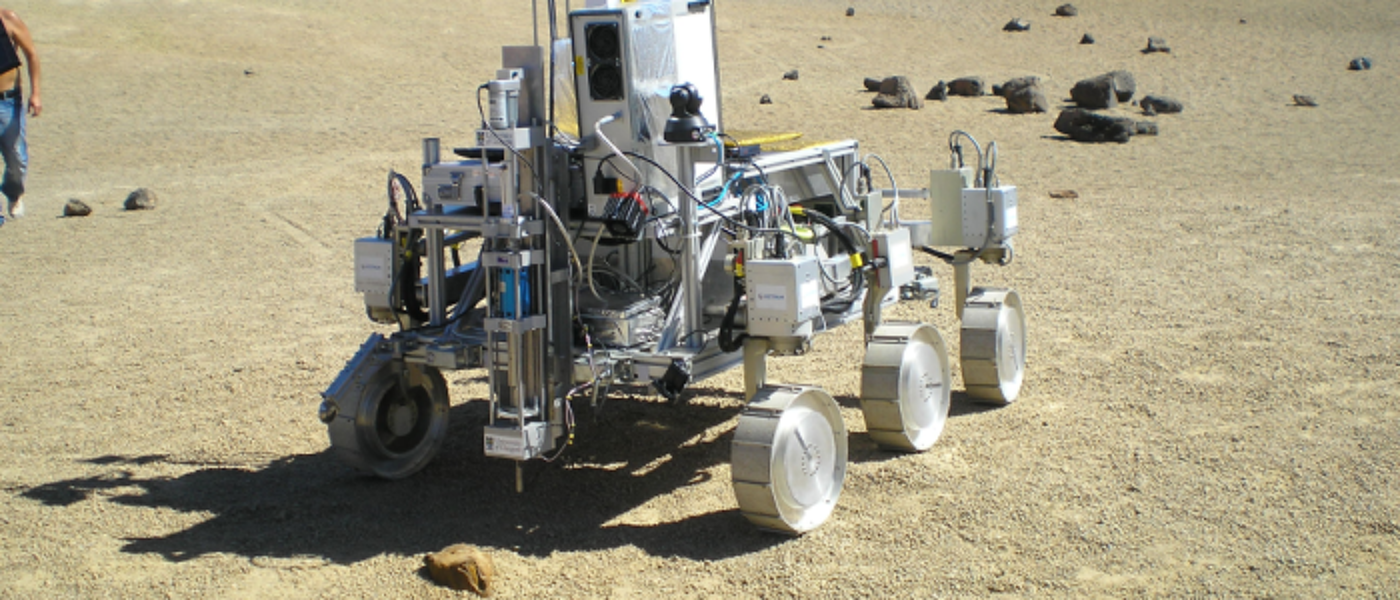

Exploration

Ultrasonics can be used in the examination of materials for hidden defects and ensuring weld joins are correct. It is also used to join materials together, such as for cutting, drilling, and forming, or for detection, such as in parking sensors. These capabilities can be combined to produce highly advanced ultrasonic exploration technology. Coupled with measurements of surroundings, ultrasonic vibrations can also be used in the extraction of rock and ice samples in extreme environments, from Antarctica to extra-terrestrial environments. We are also interested in deployable structures for low-earth orbit and space applications.

Notable Staff: Dr Patrick Harkness, Dr Kevin Worrall, Prof Margaret Lucas

Key Projects: BADGER

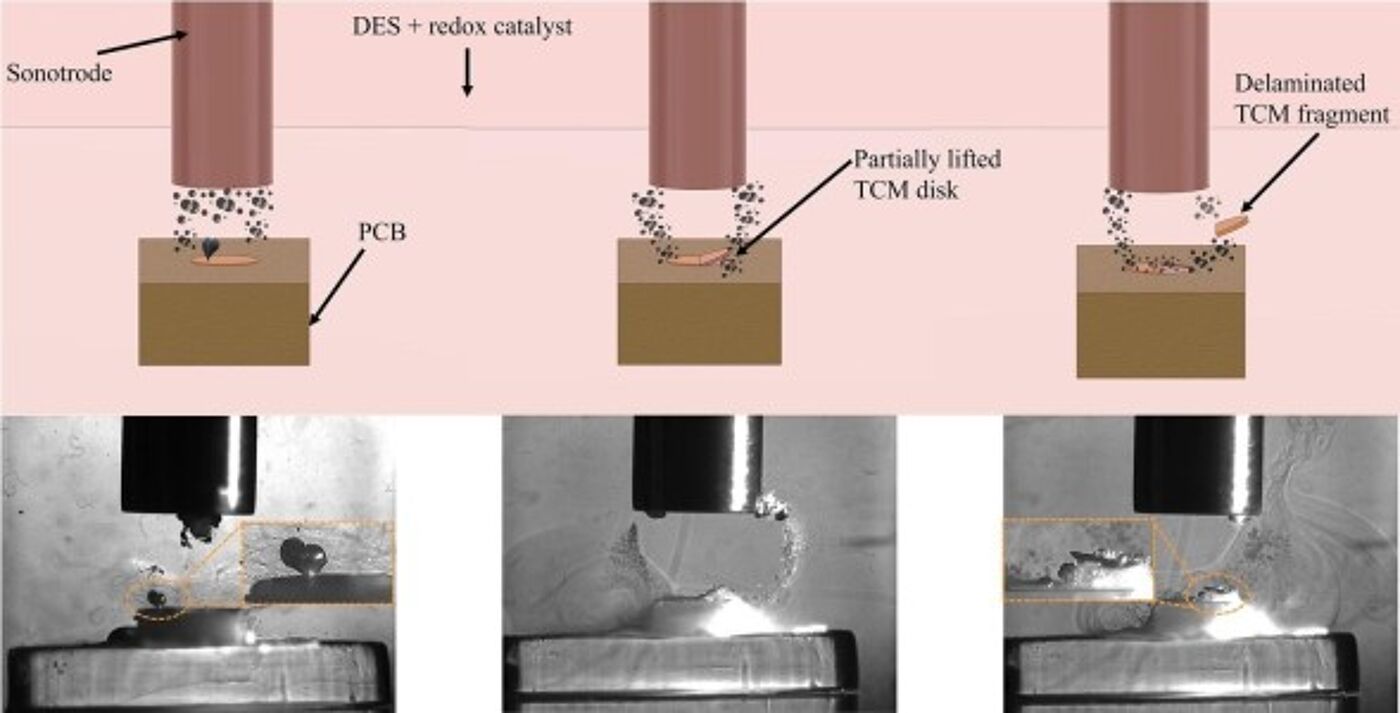

Acoustic Cavitation and Hydrometallurgy

Acoustic cavitation can be used in the process to liberate materials such as oil from targets such as porous rock. We are investigating how ultrasonics can deliver highly effective processing and recovery of valuable minerals from different materials including ores, and for the recycling of e-waste. One method of such green processing is by sonocatalysis in deep eutectic solvents. Here, we are investigating new ultrasonic-based methods to enhance such effects for the sustainable processing of materials, including recycling.

Notable Staff: Dr Andrew Feeney, Dr Paul Prentice

Metrology

Ultrasonic transducers are vital for a broad range of applications in a range of environments, for example from domestic water metering to flare gas measurement. Flexural ultrasonic transducers have received increasing attention in recent years and are being investigated for measurement in liquid and gas into the hundreds of bar pressure and hundreds of degrees Celsius. There are now demands for measurement in fluids such as hydrogen. We are focusing on addressing the key engineering challenges associated with enabling ultrasonic devices for such environments.

Notable Staff: Dr Andrew Feeney

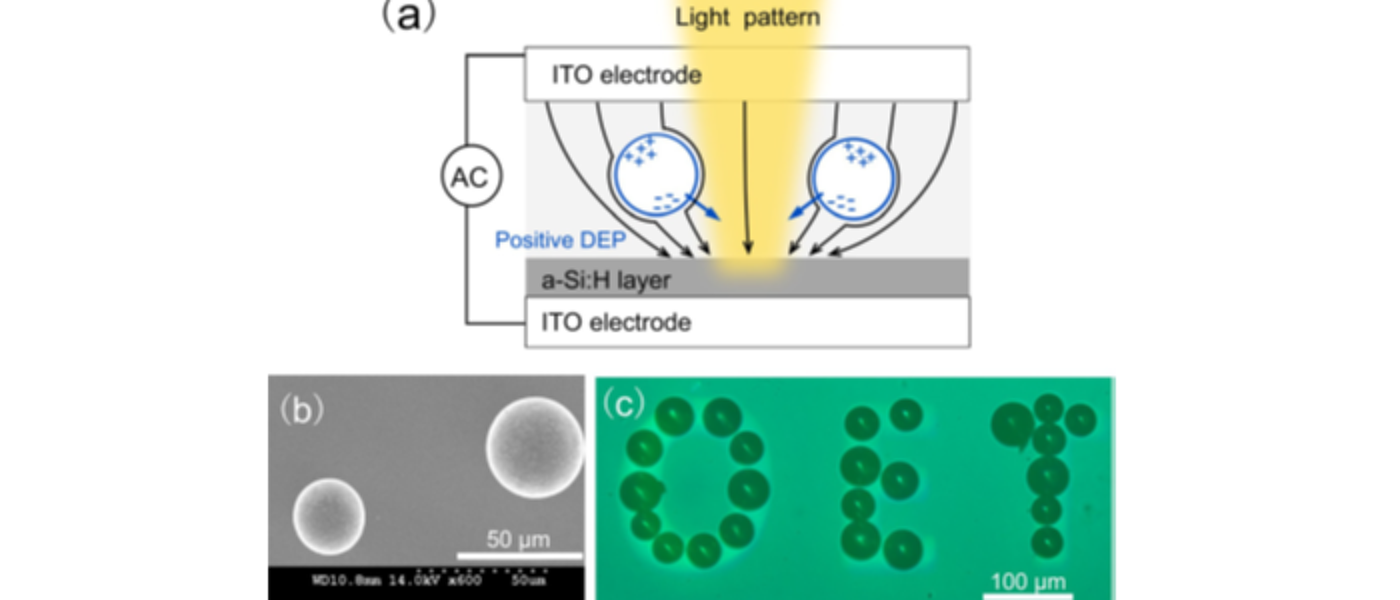

Micromanipulation

Our research into micromanipulation means we can interact with different materials with ‘touchless’ technologies such as optoelectronic tweezing and optical tweezing. Patterned light can be used to generate the electric fields gradients necessary to create the required forces for manufacturing electronic components, including reconfigurable circuitry. We have been able to demonstrate ‘manufacturing with light’, where we have successfully undertaken the micro-assembly of optoelectronic microstructures using optoelectronic tweezers. In other research, we have also been able to achieve high-density data encoding with plasmonic nanopixels.

Notable Staff: Dr Steven Neale

Key Projects: Micromanipulation

Destructive Tools and Devices

Our expertise encompasses the design, fabrication, and optimisation of ultrasonic devices and tools for forming, welding, cutting, compaction, and drilling processes. Examples of specific applications include ultrasonic cutting of food products, metal forming, and the joining of dissimilar materials through targeted ultrasonic vibrations. Our drilling capabilities have crossed over into the development of rock sampling devices for extra-terrestrial environments. We have also conducted leading research into nonlinear vibration responses, which are vital to understand for improving industrial ultrasonic processes.

Key Staff: Prof Margaret Lucas, Dr Patrick Harkness

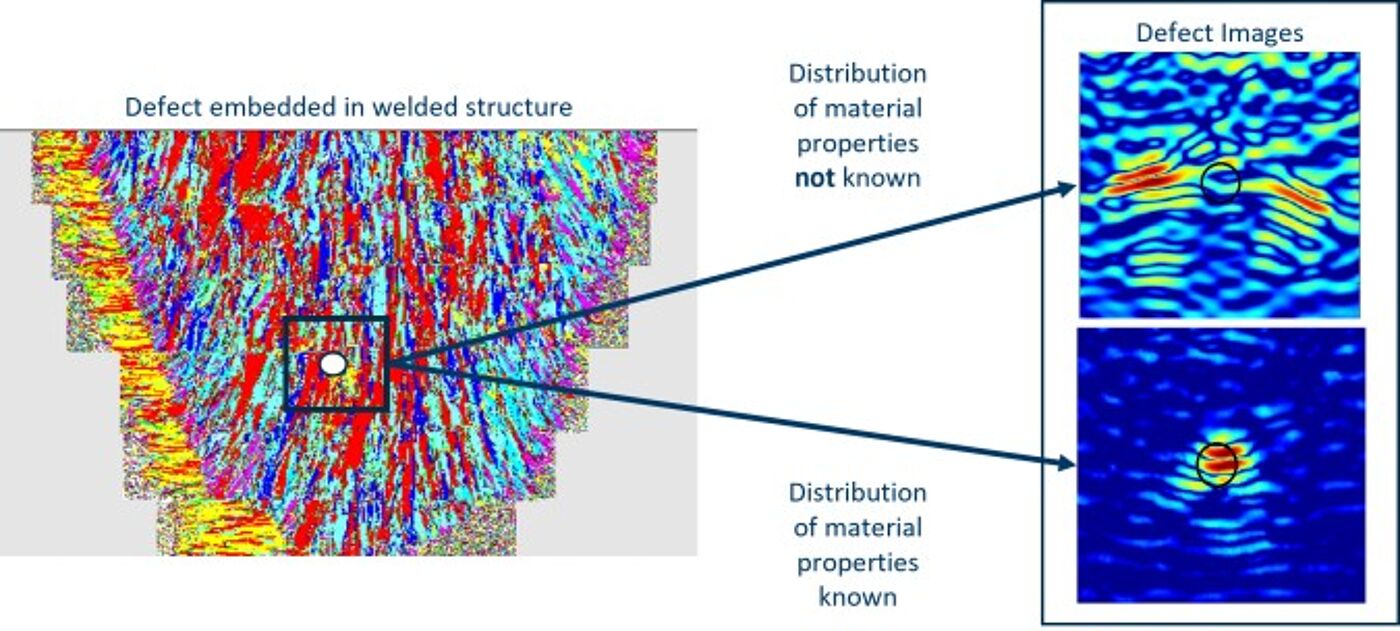

Imaging and Tomography

The oil and gas, nuclear and aerospace industries are just a subset of the sectors dependent on the routine maintenance of safety critical structures. To mitigate the risk of catastrophic failure, the structural integrity of key components within these industries must be assessed regularly. Ultrasonic non-destructive evaluation (UNDE) is a technique which involves the transmission of mechanical waves through a solid object. Just like in medical ultrasound, these waves can be passed through the object without disturbing its internal composition, and the scattered wavefield can be recorded resulting in large quantities of noisy data. To better understand how waves interact with different structures we can build mathematical models of their propagation and, based on these models, we can develop novel algorithms and frameworks to decipher the noisy recorded data to characterise spatially varying material properties and create meaningful images of the interior of solid objects.

Notable Staff: Dr Katy Tant