Research breakthrough could enable future generations of self-sensing materials

Published: 7 October 2024

Breakthrough research that eliminates the guesswork in developing advanced 3D printed materials could help accelerate the development of new forms of ‘self-sensing’ aeroplanes, robots, bridges and more.

Breakthrough research that eliminates the guesswork in developing advanced 3D printed materials could help accelerate the development of new forms of ‘self-sensing’ aeroplanes, robots, bridges and more.

A team of engineers led by researchers from the University of Glasgow have developed the first system capable of modelling the complex physics of 3D-printed composites capable of detecting strain, load, and damage using nothing more than a measure of electrical current.

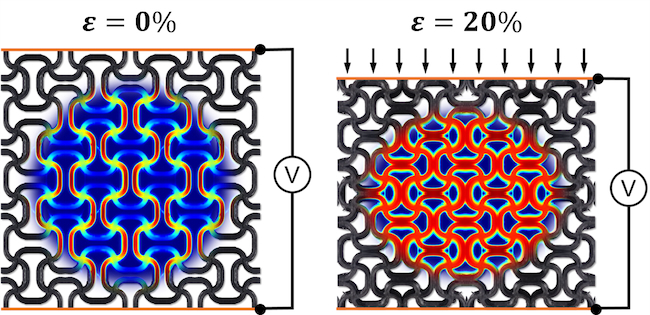

Visualizing the smart behaviour of a self-sensing material: The image shows how an intelligent material can sense changes in its own shape/state. As the material is squeezed (left: no squeeze, right: squeezed by 20%), the way electricity flows through it changes. This ability to ‘feel’ and detect changes could be used, for e.g., in automotive or aerospace applications to monitor the health of vehicles or aircraft in real-time, improving safety and performance.

By allowing material scientists to predict in advance for the first time how new structures can be fine-tuned to produce specific combinations of strength, stiffness, and self-sensing properties, it could help catalyse the development of revolutionary new applications for the technology.

In the aerospace and automotive sectors, new materials produced using the team’s insights could enable real-time monitoring of structural integrity in aircraft, spacecraft, and vehicle components, enhancing safety and maintenance efficiency.

For civil engineering, these materials could enable developments in smart infrastructure by providing continuous assessment of the structures of bridges, tunnels, and high-rise buildings, highlighting problems long before they lead to collapse. They could offer similar benefits for robots at work in automated manufacturing, or even help soldiers on the battlefield keep tabs on the integrity of their body armour plates.

3D printing, also known as additive manufacturing, enables the creation of complex structures by building them layer by layer from materials like plastics, metals, or ceramics.

As technology has developed, researchers have been able to create increasingly complex materials with unique properties. Introducing a lattice of honeycomb-like chambers to the structure’s interiors, for example, can allow materials to delicately balance weight with structural strength.

Weaving fine strands of carbon nanotubes throughout materials can allow them to carry an electrical current, imbuing them with the ability to monitor their own structural integrity through a phenomenon called piezoresistivity. When the readout of the current changes, it can indicate that the material has been crushed or stretched, allowing action to be taken to address the fault.

Professor Shanmugam Kumar, of the University of Glasgow’s James Watt School of Engineering led the research, which is published as an article in the journal Advanced Functional Materials. He said: “Imparting piezoresistive behaviour to 3D-printed cellular materials gives them the ability to monitor their own performance without any additional hardware. That means we can imbue cheap, relatively easy-to-manufacture materials with the remarkable ability to detect when they have been harmed and measure just how damaged they are. These types of lattice materials, which we call autonomous sensing architected materials, hold significant untapped potential to create advanced applications across various fields.

“While researchers have known about these properties for some time now, what we’ve not been able to do is provide a way to know in advance how effective new attempts at creating novel self-sensing materials will be. Instead, we have often relied on trial and error to determine the optimal approach for developing these materials, which can be both time-consuming and costly.”

In the paper, the researchers describe how they developed their system through a rigorous set of lab experiments combined with modelling.

They used a plastic known as polyetherimide (PEI) mixed with carbon nanotubes to create a series of four different lightweight lattice structure designs. These designs were then tested for their stiffness, strength, energy absorption and self-sensing capabilities.

Using sophisticated computer modelling, they developed a system aimed at predicting how the materials would respond to a varied set of loads. They then validated their multiscale finite element model’s predictions by subjecting the materials to intense analysis under real-world conditions, utilizing infrared thermal imaging to visualize electrical current flowing through the materials in real-time, leveraging the analogy between heat and current flow within these materials.

They found that their models could accurately predict how the materials would respond to various combinations of stress and strain, and how their electrical resistance would be affected. The results could help underpin future developments in additive manufacturing by providing insights into how proposed new materials will perform before the first real-world prototype is printed.

The research builds on previous developments from the team, who recently published a paper showcasing another approach to modelling which enables researchers to predict how additive manufacturing-induced flaws can affect the structural integrity of any new design.

Professor Kumar added, “With this study, we have developed a comprehensive system capable of modelling the performance of self-sensing, 3D-printed materials. Informed by rigorous experimentation and theory, it represents the first system of its kind that enables the modelling of 3D-printed materials across multiple scales and incorporates multiple types of physics.”

“While we focused on PEI materials with embedded carbon nanotubes in this paper, the multiscale finite element modelling our results are based on could be easily applied to other materials which can be created through additive manufacturing too.

“We hope this approach encourages other researchers to develop new autonomous sensing architected materials, unlocking the full potential of this methodology in material design and development across a wide range of industries.”

Mattia Utzeri, a former PhD student in the Sustainable Multifunctional Materials and Additive Manufacturing (SM2AM) Laboratory at Glasgow and currently a researcher at the Polytechnic University of Marche in Italy, along with a collaborator at Istanbul Technical University in Turkey, contributed to the work. The team’s paper, titled ‘Autonomous Sensing Architected Materials’, is published in Advanced Functional Materials.

First published: 7 October 2024